Supply Chain Management

Build A Global Supply Chain That Is Win-win and Sustainable for Cooperation

As an influential enterprise in the automotive parts industry, Minth Group attaches great importance to the sustainable development of the supply chain. It is deeply aware that the emission reduction of the enterprise value chain cannot be achieved without the joint efforts of upstream and downstream and even the entire industry. Therefore, while doing a good job in its own emission reduction work, it continuously carries out supply chain cooperation and communication.

On one hand, Minth Group helps the supply chain reduce emissions in various ways such as collecting carbon emission data of the supply chain, formulating carbon neutrality goals, incorporating emission reduction requirements into supplier access and assessment, and carrying out low-carbon empowerment of the supply chain. Through low-carbon practical applications, it continuously expands its global influence. On the other hand, it actively purchases green aluminum and green steel, closely cooperates with suppliers to establish sustainable procurement practices, encourages suppliers to operate in an environmentally friendly and socially responsible way, attaches importance to ESG-related risks in the supply chain. According to the SA8000 standard, it formulates a supplier sustainable development commitment letter, establishes a comprehensive supplier guide to ensure compliance with labor standards, health and safety regulations, environmental protection, business ethics, and conducts effective upstream supplier management. It also actively participates in the Aluminium Stewardship Initiative (ASI). With an open attitude, Minth Group continuously pays attention to the ESG performance of suppliers and looks forward to building a carbon-neutral ecology with high-quality partners from all over the world and jointly building a responsible, compliant, win-win and sustainable global supply chain.

Supplier Management Policy

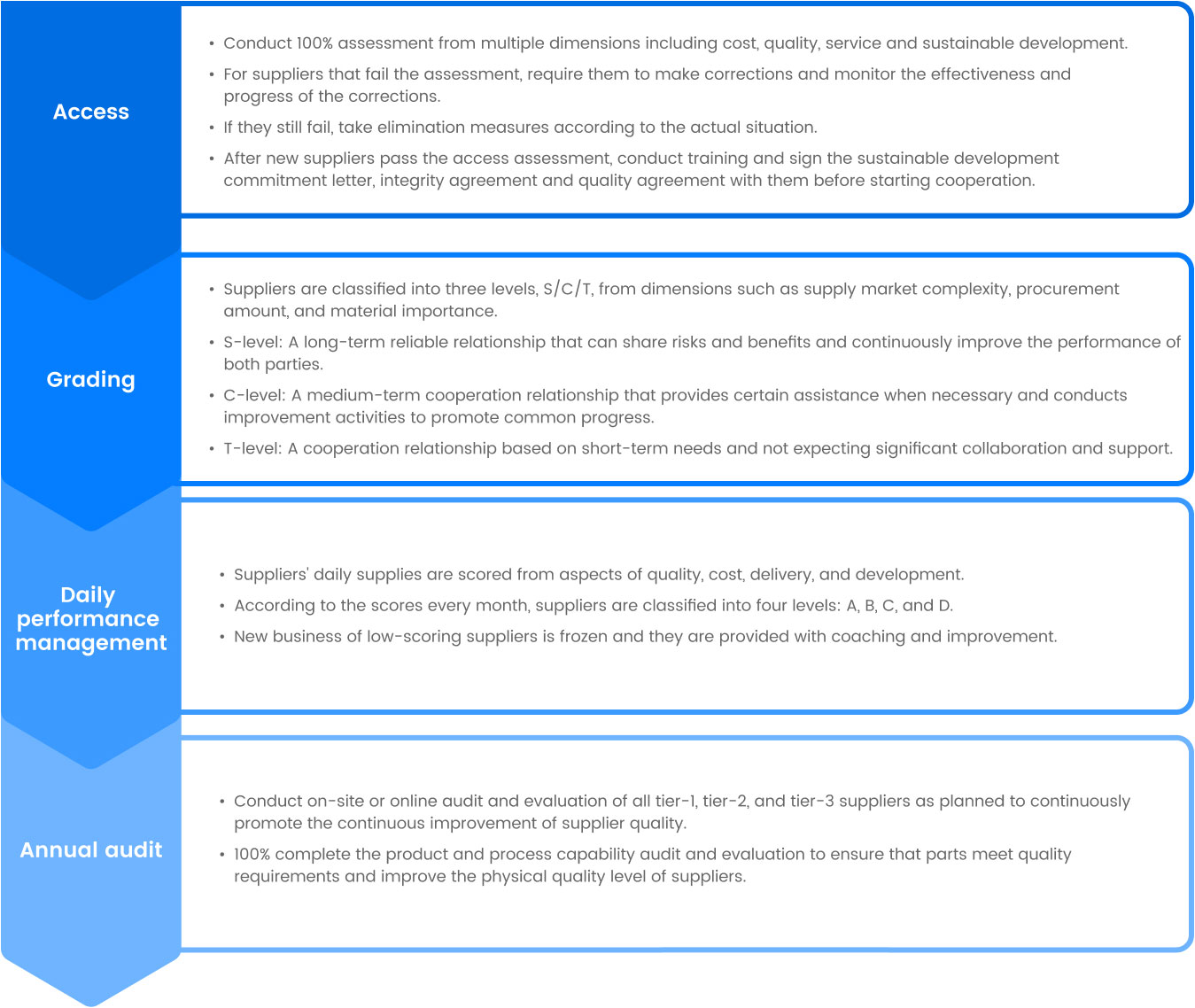

Minth Group complies with the laws and regulations of the countries where it operates and formulates detailed policies such as the "Minth Group Supplier Code of Conduct", "Process Audit Management Guide", "Minth Supplier Management Manual", " General Terms and Conditions", "Supplier Risk Management Guide", "Supplier Information Management Guide" and "Supplier CSR Management Guide". In 2024, we revised the "Supplier Performance Management Guide" and took sustainable development as a new requirement for suppliers' monthly performance. In all links such as supplier sourcing, access and elimination, audit and evaluation, performance evaluation, and communication, a strict and complete management process system is set up to ensure closed-loop management of the entire process and life cycle of the supply chain. In 2023, the release of the sustainable development commitment letter was completed. In 2024, the sustainable development commitment letter was revised, adding requirements such as supporting conflict mineral policies, due diligence investigations, traceability investigations, and carbon emission statistics.

Sustainable Supply Chain

To achieve sustainable development of the supply chain, Minth has strict requirements for the business ethics performance of purchasers and suppliers. In 2023, the code of conduct for purchasers was released to establish a professional procurement team. Suppliers are required to sign an integrity agreement to manage their employees, prohibit corrupt and criminal acts, and encourage supervision and reporting through compliant reporting channels. In 2023, the activity of "Guardian of Integrity Action" was continuously carried out, and the signing of integrity notification letters deepened the construction of integrity.

-

Conflict Minerals Management

Minth Group's global sustainable procurement policy covers all materials, including conflict minerals (tin, tungsten, tantalum, and gold) mined in conflict areas such as the Democratic Republic of the Congo (DRC) and its neighboring countries. The group conducts risk assessments throughout the supply chain using a reporting template compiled by the Responsible Minerals Initiative (RMI), a coalition of more than 400 global companies and organizations. Suppliers to Minth Group whose products may contain conflict minerals must fill out and submit the reporting template annually. -

Raw Material Quality Control

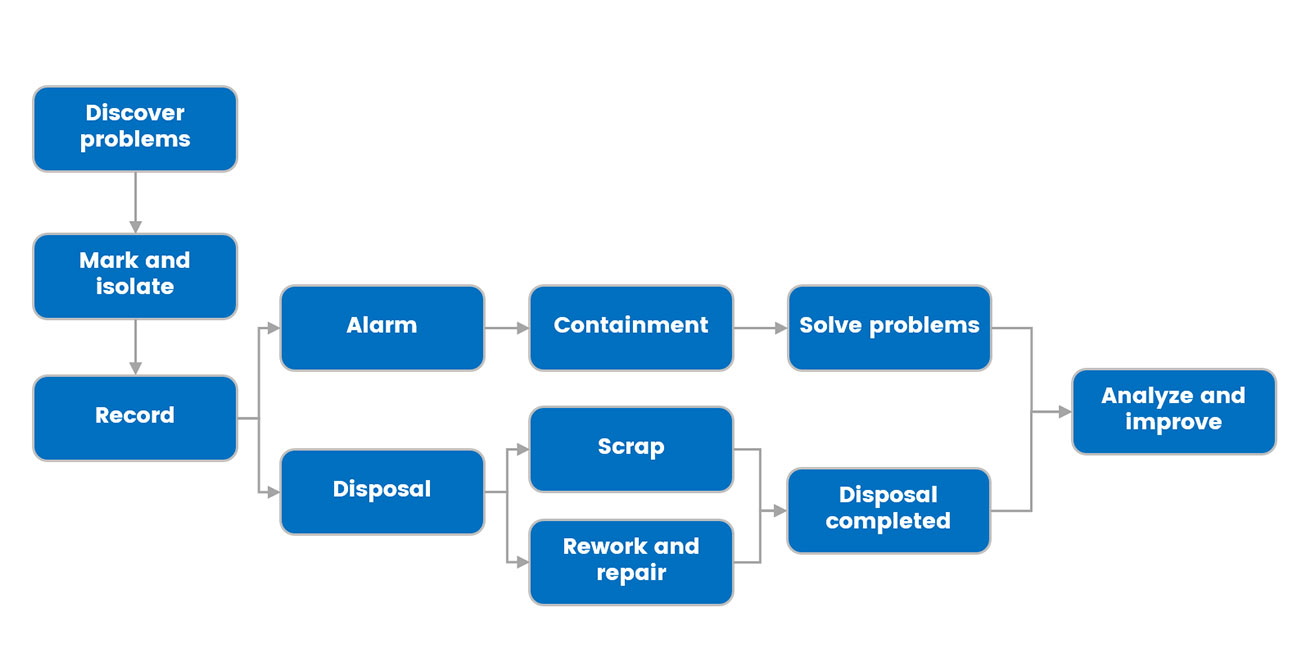

The company conducts systematic management of all raw materials. From product development to production, while ensuring the quality of raw materials, it insists on selecting raw materials with a lower environmental footprint to reduce environmental impacts from the source. We have formulated documents such as the "Raw Material Development Management Guide" and "Material/Accessory Inspection Specifications" to clarify inspection rules such as raw material inspection items, detection methods, inspection frequencies, and judgment criteria for incoming material inspection to ensure the quality of raw materials and further guarantee the quality of products. For discovered problems, in accordance with the "Non-conforming Product Management Procedure", the process of handling non-conforming products is standardized from two dimensions of business process and on-site process to strictly control quality.

Green and Environmentally Friendly Materials

We give priority to purchasing environmentally friendly materials such as green aluminum, green steel, and recycled/recyclable plastics. By integrating these sustainable materials into the production process, we aim to minimize environmental impacts and contribute to creating a more sustainable future.

-

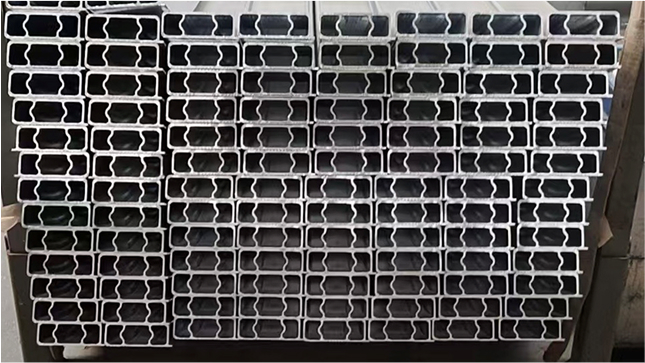

Hx11 front bumper beam: Aluminum Billet EA7003D278L800

-

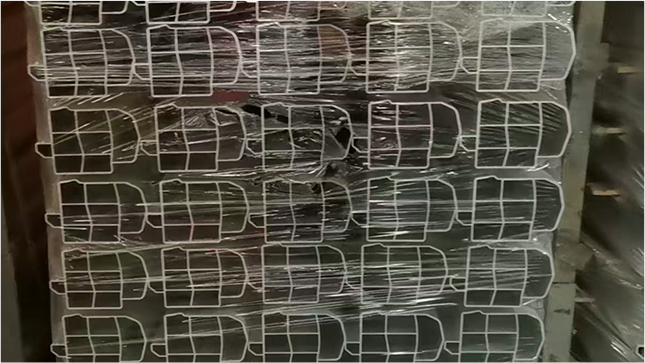

v216 rocker panel:Aluminum Billet EA6082D278L800

Supplier Empowerment

-

Minth attaches great importance to the improvement and cultivation of suppliers' capabilities and pursues to establish a stable and mutually beneficial cooperative relationship with suppliers, striving to achieve mutual benefit and win-win results. In 2024, through diversified interactive empowerment activities such as supplier conferences, training courses, and audit coaching in both online and offline forms, Minth helps all suppliers improve their capabilities and assists them in meeting Minth's expectations in aspects such as product safety, quality assurance, environmental protection, and sustainable development, including IATF16949 quality requirements, new product development, quality problem analysis and resolution, product quality standards, and specific requirements from OEMs.

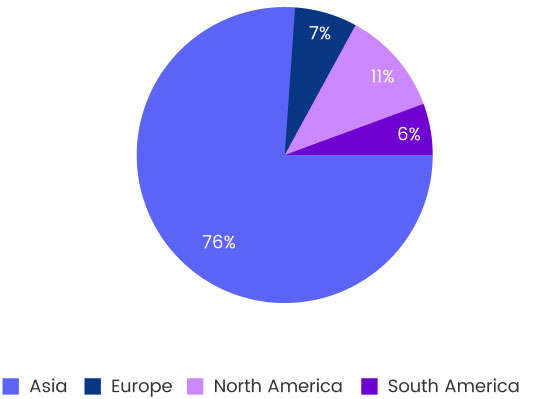

Proportion of Global Suppliers