Environment

Our Commitment to a Sustainable Future

- Climate Change and Carbon Neutrality

- Reducing Our Environment Footprint

Achieving CO2 Net-Zero by Three Steps

Minth Group is committed to combating climate change by setting ambitious targets for carbon neutrality across our global operations with following steps:

-

by 2030

We target to peak our carbon emission while our business will continue to grow vigorously as expected. -

by 2040

We target to achieve operational carbon neutrality in scope 1 and 2. -

by 2050

We aim to achieve value chain carbon neutrality including our scope 3 emissions.

To achieve these goals, Minth has formulated a feasible emission reduction pathway and promote emission reduction measures in a step-by-step and focused manner in our operations and value chain. Upholding the concept of 'Green and Intelligent Manufacturing and Sustainable Development', Minth is committed to increasing investments in clean technologies, leading the promotion of environmental protection, and actively boosting the green upgrade of the industry.

-

Scope 1 & 2: Navigating Green Route We Operate

In terms of scope 1 and scope 2 emissions, Minth is accelerating the decarbonization process by improving energy efficiency, increasing the use of renewable energy through on-site generation and potential off-set purchase. We are taking decisive steps to enhance energy efficiency through equipment modification and system upgrades, with an annual goal of reducing energy intensity by 5% set in 2022. -

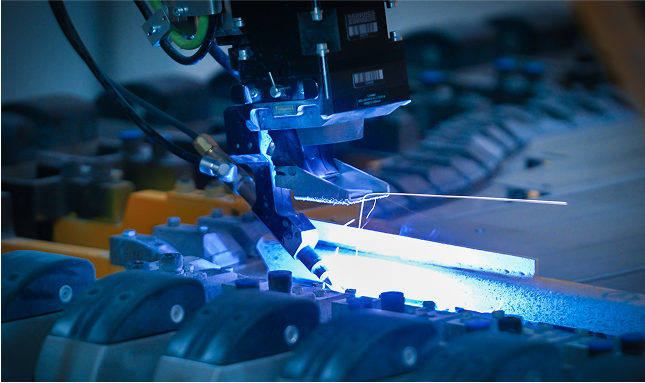

Case 1 : Air Compression Reforming in The Production Line

In one of our production lines, the power of both the main and auxiliary air compressors is 55kW, and they are always turned on at the same time at the high demand. However, the auxiliary compressor cannot automatically shut down with the decreasing of demand.

With the factory's lean manufacturing and carbon reduction deepening, the control logic is changed by adding relays and pressure sensors to the auxiliary compressor so as to achieve automatic start and stop. The auxiliary air compressor can only start automatically when the pressure is below 0.65 Mpa, which has reduced the energy consumptions. After this reforming project, an amount of 75MWh electricity consumption is saved per year.

Scope 3: Expanding Sustainable Products

-

Recycled Aluminum Production Line Situation

- ABS, PC+ABS, PP, etc.

- Enhance the original properties of recycled plastics

- Reduce dependence on raw petroleum resources

- Decrease the generation of plastic waste

-

Recycled Engineer Plastics

- Bio-based elastomer materials

- Excellent weather resistance

- Excellent heat aging resistance

-

Eco-alumin Aluminum Series

- Recycle up to 75% of aluminum materials

- Carbon emissions of aluminum billets are ≤ 2.5kg CO2/kg

- Excellent mechanical properties

- Excellent crush resistance

- Excellent corrosion resistance

-

Recycled Aluminum Production Line Situation

Minth Chinese factory has green raw aluminum ingots, green aluminum billets, and scrap aluminum resources, and has the production technology capability of ≥ 75% recycled aluminum casting billets; Minth Serbian factory not only has the ability to melt and cast aluminum billets with ≥ 75% recycled materials, but also uses 100% green electricity in the entire processing flow of melting, extrusion, machining, and so on. In Minth Mexican factory, it also has green aluminum rod resources with ≥ 50% recycled aluminum.

Water Recourses Management

Minth adheres strictly to the laws and regulations concerning the protection of water resources in all the areas where we operate. As a global enterprise, we pay close attention to the increasing scarcity of water resources, and conduct analysis of our operational locations using the Water Risk Filter provided by the Worldwide Fund for Nature (WWF). We manage water recourses by exploring more of recycling, reusing and alternative water sources.

-

Case 2 : Steam Condensate Recycle Reforming in the Production Line

In one of our production lines, the previous water replenishment system for rinse tank in pre-coating treatment is discharged directly. With the factory focusing on water resources management, for both reducing environmental footprint and cost, the steam condensate water starts to be recycled and redirected to rinse tank. As a result, more than 1,500 tons of water could be saved per year with economic benefit of 50,000 USD per year. -

Renewable Energy

In recent years, we are promoting the use of distributed photovoltaic power as part of energy transition. Minth has already installed a 70MW of solar energy generation capacity in factories of China, Thailand and Serbia. We are trying to make best use of factory roofs, parking lots, and other resources to keep increasing the use of distributed photovoltaic generation, with the goal of a total annual PV generation capacity of 300 GWH by 2040. In addition, we are working on the feasibility of Net-zero Factory in global operations to set examples for all our plants.

-

Waste Management

Reducing waste and promoting recycling is one of the priorities of Minth. We have established a comprehensive hazardous waste management system that monitors every stage from generation, transportation, storage, to disposal. This system enables open and transparent information about hazardous waste management. Minth has set a target to decrease the hazardous waste generated intensity by 25% by 2030 compared to 2019.