Quality Management

Creating Customer Value and Trust

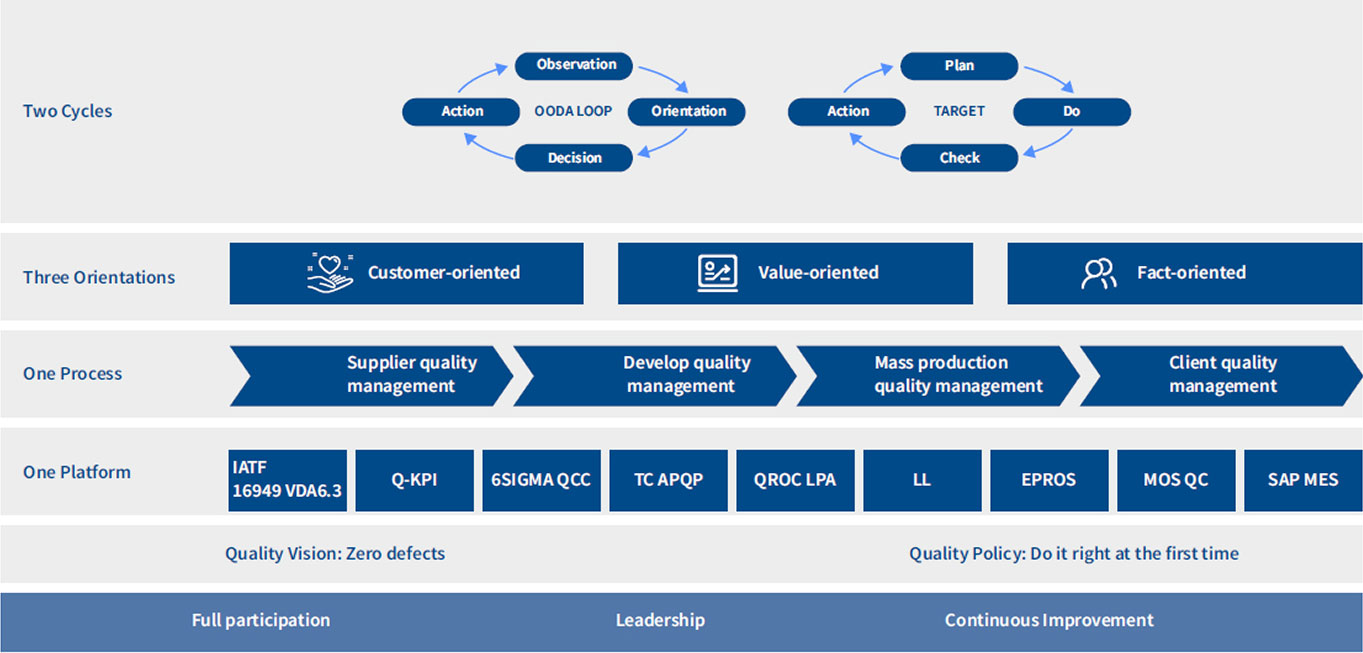

The Mission Statement to engage every employee in contributing to the creation of high-quality products, services and solutions that exceed customer’s expectations through innovation and continuous improvement.We are leveraging on a global framework to proactively identify, prioritize and address customer quality issues in keeping with the intentions of Minth founder to the Group’s Mission of “Serving Customer with Superior Quality”The Group Quality Department has developed a standardized quality management map based on global best practices to achieve superior quality throughout the entire value chain, across all businesses and globally.

Goals and KPI

To achieve our mission of “Serving Customer with Superior Quality”, we established goals, including:

In order to achieve these goals,

- The Group is disseminating the quality vision, policy and strategy to all employees worldwide.

- Achieving IATF16949 Automotive quality management system certification at all of the Group’s manufacturing sites.

- ESG(Monitoring quality-related items regarding environmental, social and governance)

Global Quality Governance

Excellent products and services are the foundation of the company. The Group Quality Department, in collaboration with the 4 product lines, guides and supports the global bases through customer performance improvement, continuous improvement, quality empowerment activities, etc.

Group Quality Department has developed a standardized quality management map based on the best practices to achieve the production of safe and high-quality products throughout the entire value chain, across all businesses and globally., thus providing customer satisfaction and maintaining customer trust.

Global Quality Management System

We strictly follow the laws and regulations related to quality management, According to the requirements of IATF16949:2016 standard, we have formulated a complete quality manual and management program, and from the preliminary prevention, preliminary planning and preliminary control, we have formulated APQP product advance planning management program, and for the product quality and safety control, we have formulated “product release management program” and “product safety management guide”.

Through 6sigma, QCC tools, digital means to improve the quality process management, and then through the LPA layered audit, VDA6.3 process audits, VDA6.5 product audits, etc. to achieve the quality management system to continue to assess the effectiveness of the system and the process, in order to provide customers with the highest quality of products, services and problem-solving solutions.

Quality Prevention Activities

The entire value chain (product design, development, project management, procurement, manufacturing process, sales and customer service) applies IATF standards, CQI standards, VDA standards, and the application of risk-based thinking is promoted at all levels of the entire value chain.

Particularly during development and production, the Group implements APQP manuals for Design Failure Mode and Effects Analysis (D-FMEA) and Process Failure Mode and Effects Analysis (P-FMEA), while cross-functional teams conduct periodic design reviews at each stage of the process.

The Group also continuously monitors the quality of the manufacturing process and the assessment of the final product to meet regulatory and customer requirements.

The Group continuously monitors the quality KPIs of each BU in order to trigger actions at an early stage and exchange and share innovative quality management, best practices and lessons learned to prevent the recurrence of quality issues.

Quality Assurance from Suppliers

The Group procures raw materials and accessories from a wide range of suppliers. In order to maintain and continuously strengthen quality assurance throughout the value chain, the Group applies the highest quality standards to all suppliers and business partners, including N-tier suppliers, who are required to comply with procurement contracts and its global sustainable procurement policy. To ensure high quality, the Group has also established Group-wide standards for auditing suppliers of raw materials and accessories.

The Group's Supplier Management Center continuously monitors the quality of the goods received, audits suppliers and takes measures to ensure that suppliers maintain a high quality assurance system and provide products that consistently meet their quality requirements.

Outsourced Quality Assurance

Globally, the Group is constantly working with partners and suppliers to improve the overall quality of outsourced products and provide customers with superior quality. This includes providing training and other supplier developments, instilling high quality standards and standards to ensure that any potential issues are identified early.

Quality Assurance During Development

In order to ensure the quality of design and development worldwide, the Group Development Center has published the APQP process and continuously optimizes the process. Align with Advanced Product Quality Planning (APQP) process requirements and collaboration, including mission-critical tasks from concept approval to production. Its purpose is to develop product quality plans, develop and manufacture products that meet customer requirements.

To ensure quality assurance in the development process, deliver successfully and constantly look for opportunities to optimize the development process for all product development teams. The scope covers the entire product life cycle, including the development process, the production process and after-sales.

The development process is based on quality valve management. In each nodal valve, all defined standards must be met to ensure the achievement of development objectives, including risk analysis, as well as the safety and quality of the final product.

Quality Assurance in The Manufacturing Process

The Group has fully introduced the five tools of the automotive industry, continuously improving the global manufacturing process through the introduction of innovative technologies, digitalization, and advanced inspection technologies, creating industry-leading products, services and problem-solving solutions to meet growing customer expectations.

Identify potential quality risks at production sites and proactively implement preventative measures using Failure Mode and Effects Analysis (FMEA) quality assurance methodologies and focusing on critical quality inputs.

The MSA measurement management system, one of the five major tools in the automotive industry, has been fully introduced, and process documents such as "Monitoring and Measuring Device Management Procedures" and "MSA Management Guidelines" have been formulated to prevent the occurrence of quality and safety problems caused by measurement system failures. Different product lines have formulated relevant product inspection measures according to their own business characteristics, and conducted targeted audits on key projects. We have high-precision product testing and testing capabilities, and have obtained the ISO17025 laboratory qualification certification, in the development and mass production stages of the product are effective for all-round inspection and testing, such as the use of advanced lidar, multi-eye vision, imported three-dimensional measuring machine to measure the full size of the product or key dimensions; Advanced weld inspection and metallographic microscope are used to test the weldability of products; Use self-developed gas inspection, water inspection, helium detection and other air tightness testing equipment to test the tightness of the product 100%; The use of imported cleanliness testing equipment, product cleanliness and other characteristics of the test;

We have developed an SPC system with automatic online monitoring, which can effectively monitor process parameters, product measurement results, alarm or shutdown in case of abnormalities, and prevent product quality problems in advance.

We have made a huge breakthrough in automatic inspection technology, using 100% of the time in multiple inspection stages of multiple projects.

Customer Performance and Customer Satisfaction Guarantee

The Group Quality Department prepares quality management white papers for key customers to share innovative quality management, best practices and lessons learned to meet regulatory and customer requirements.

Continuously monitor the performance of the customer system, establish the "Customer Performance Management Guide", Monitor and guide action plan for red and yellow performance plants. After the problem solution is completed, the lessons learned are shared in the internal system, and the same type of products are horizontally developed in each subsidiary around the world to prevent the recurrence of quality problems.

Digital Quality Assurance

Digital systems are deeply integrated into our day-to-day quality management processes. We use various systems to effectively manage the whole process of "supplier-design-manufacturing-customer service". These systems allow us to track quality data, conduct internal quality audits, resolve quality issues, and provide staff training in an efficient manner. By leveraging digital technology, we have enhanced our overall quality management capabilities, optimized processes, and improved quality control and customer satisfaction.

In terms of quality management processes, we have taken the following measures:

1. Integration of SAP (Enterprise Management Solution) and MES (Manufacturing Execution System) to achieve end-to-end quality management and traceability. This includes conducting product inspections and managing non-conforming products.

2. Utilize the QBOM system to ensure the accurate transmission of quality inspection standard data from development to mass production.

3. Implement the "Lessons Learned" (LL) system to accumulate and record quality knowledge, experience and lessons.

4. Established a QMS platform: deployed a hierarchical audit system, a process audit system, a product audit and a system audit to improve the digitalization of the quality audit process.

5. Launched QRQC meeting management and problem solving system to quickly respond, escalate and solve quality issues. The system can also accumulate problem-solving experience and improve the efficiency of quality management.

Global Quality Talent Skills Planning and Training

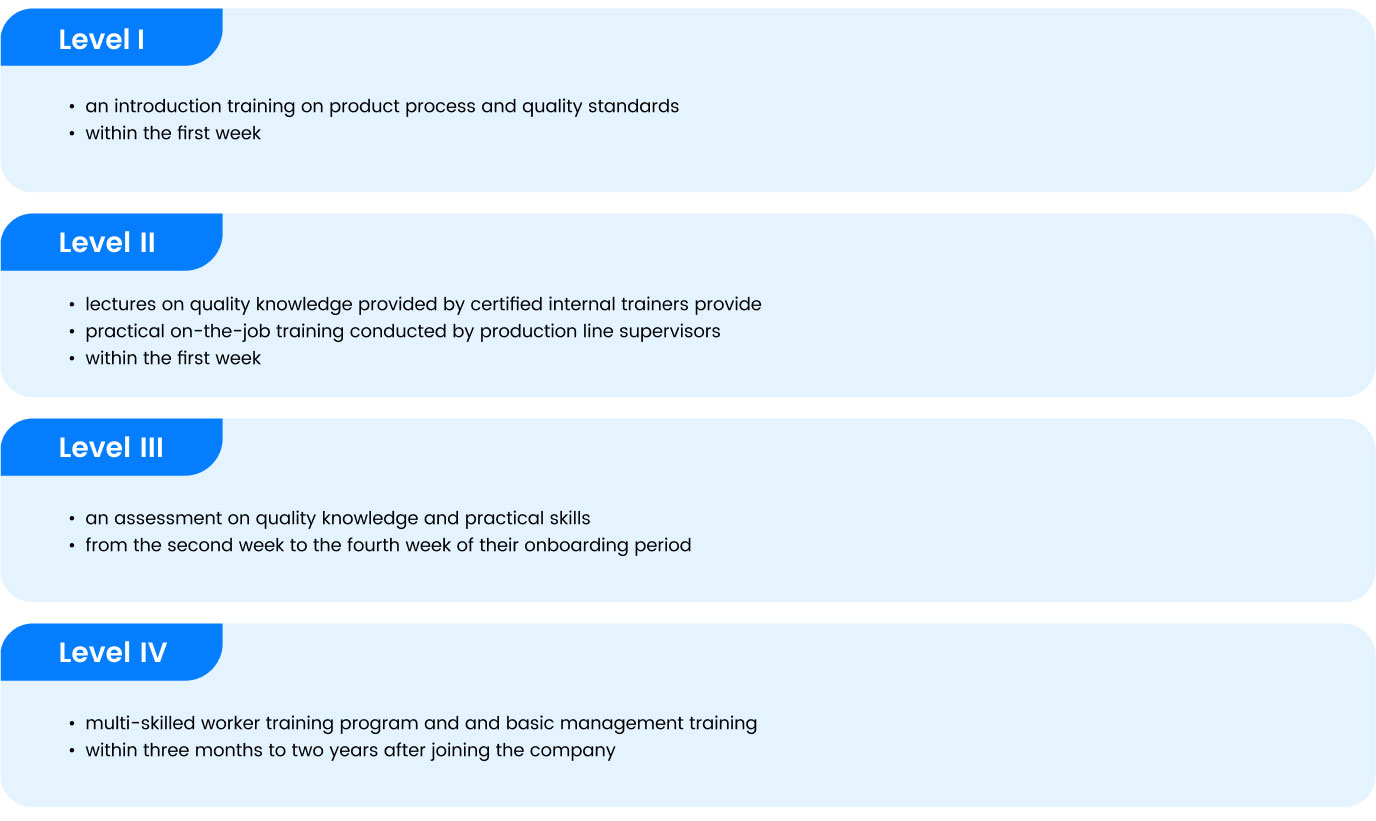

Excellent product quality is inseparable from every employee's adherence to quality. We have set up a complete quality talent skills training system and quality awareness improvement activities to help all employees produce high-quality products through exquisite skills.

From the moment we joined the company, we provide 100% quality awareness and skills training to all employees, including part-time workers, as the basis for ensuring product quality. Within four weeks of employment, all employees are required to complete the first three levels of quality training and pass the assessment at each level. If the employee will be converted to a multi-skilled worker, four levels of training will be required.

Quality Training Programs

-

Team quality training

-

VDA6.3 Process Auditor Qualification Training

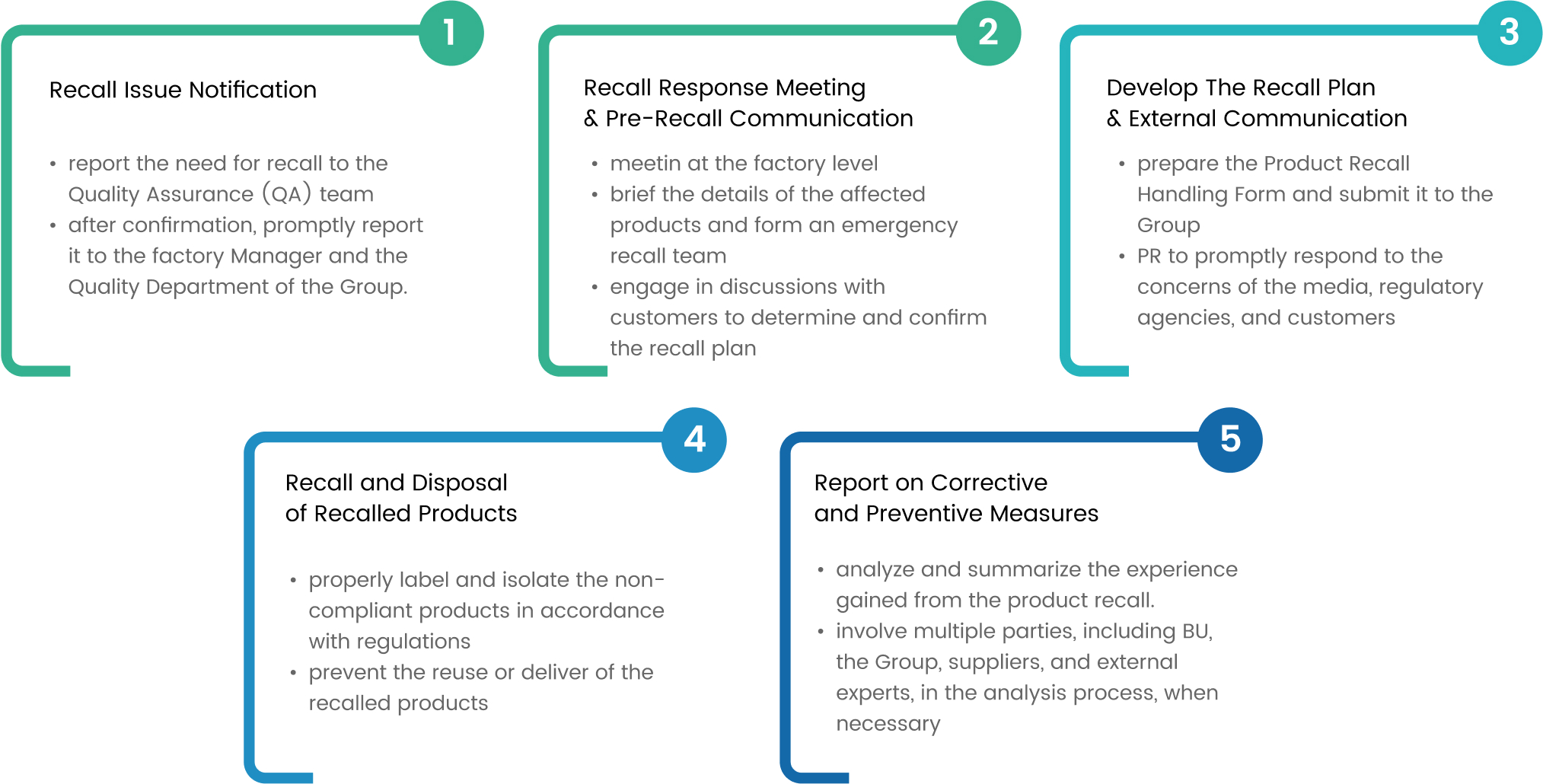

Product Recall Management

In 2023, we issued the Recall Management Guidelines to regulate and guide the timely recall of defective products.For products with defects or quality issues, we will provide free handling or recall, rectify the defects, or dispose of the products to eliminate the negative impact on customers or reduce the extent of harm caused by the products. And organizing group-wide inspections for similar issues.